Making beer, shipping beer, and refrigerating beer might all be essential steps when it comes to getting the drinks you love from those who produce it into your hands, but they come with a cost to the environment.

The creation of greenhouse gas emissions starts well before a beer makes it into a bottleshop – before it even becomes a finished product, with everything from the aluminium needed for cans and the growing and malting of grains, to the growing, processing and distribution of hops, as well as international shipping all contributing to global warming.

The Crafty Pint has regularly shone a light on how people in all parts of the beer industry are tackling these issues through our Going Green series, but a string of recent actions by breweries highlight just how far some are going when it comes to taking positive steps towards a greener future.

Today, Capital Brewing have become the first certified carbon neutral brewery under the Federal Government’s Climate Active certification. It's a certification that covers the entire business, with no exclusions: every aspect of the brewery’s existence – from the manufacture of cans to be filled with their beers, to how their barley is grown, malted and shipped – has been accounted for, reduced, or offset through the purchase of carbon credits.

“Anything that happens as a result of our organisation being on the planet, we need to offset,” says Dan Watters, who runs partnerships, community engagement, sustainability and events for the Canberra brewery (pictured above, front row, second from left).

“We wanted to give our customers the ability to choose a beer which they knew was not contributing to global warming.”

To achieve the certification Capital have been working with Pangolin Associates, who are specialists in energy management and carbon reductions. And, while other Australian breweries have achieved carbon neutral status, Capital are the first to be accredited by Climate Active – the only Australian government-endorsed carbon neutral certification – for all parts of the business.

One of Australia’s largest brewing companies, Lion, has been Climate Active certified since March 2020; however, while the electricity across its breweries, refrigerants, and even staff travelling into work is included, downstream emissions, raw materials and multiple other indirect ones are excluded from its emissions boundary.

In a media release, Climate Active’s director of strategy and engagement, Dan Sheedy, said the Capital team have shown immense dedication to being a truly sustainable business.

"[We’re] proud to have them onboard as the first brewery in the country to become carbon neutral certified for their entire operations and all of their products,” he said in a statement.

WHAT DOES CARBON NEUTRAL MEAN?

To understand the difference between the approaches to carbon neutral – a term that broadly refers to reducing and offsetting overall greenhouse emissions – you need to dive into the lexicon of scopes used in this area.

- Scope 1 refers to direct emissions under a brewery’s own control, such as fuel use, refrigerants or CO2 produced during fermentation.

- Scope 2 refers to indirect emissions purchases, such as the electricity you buy to turn on the lights.

- Scope 3 is all other emissions, which Dan at Capital says make up a significant portion of their overall emissions and is where much of their work with Pangolin Associates was directed: uncovering just what they were and how to tackle them.

“As an example, Pangolin looked at the emissions factors from the production of malt in different countries,” Dan says. They looked at how the crops are grown and processed before adding in the impact of shipping them across the world.

“A happy discovery there was that Australian malt was the most sustainably grown in the world. So we use some English specialty malts in some of our beers and now we are looking at how we can switch to an Australian malt.”

The process has seen the brewery go beyond raw materials, their choice of packaging, and how their beers end up in a beer or bottleshop too; for example, they asked their staff to find out how they were travelling to work – something Lion also include in their calculations – and believe this is an area in which there's still room for improvement.

“We surveyed all of our staff to find out how they get to work, how far they travel, and what size engine they have or whether they travel sustainably,” Dan says. “We now know that about 20 percent of the trips our staff make to get to work are sustainable, mainly through riding, but there is some skateboarding too.”

As for what’s taking place where the beer is actually brewed, their Fyshwick production brewery uses 100 percent renewable energy, they send 700 tonnes of spent grain, hops and yeast to an organic farm, and they recently upgraded their refrigeration plant.

Despite those reductions, their life-cycle assessment revealed they still had 1,120 tonnes of carbon dioxide to offset for the last financial year. After tallying their carbon dioxide output, the brewery purchased certified carbon credits from Orana Natural Capital Project. This is the nearest carbon offset project to the brewery, located near Bendigo, and uses regenerative farming, creates space for critically-endangered species, is improving biodiversity, and is also home to Australia’s largest soil carbon project.

“For us that was awesome,” Dan says. “Not only were we buying carbon credits but there was this biodiversity win as well.”

As for what’s driven the brewery to go to such lengths to achieve the certification, as anyone who knows Dan and the brewery's founders would likely attest, it’s something that’s close to their collective heart. In Dan's case, from 2008 to 2012 he ran the arts and music festival, Corinbank, which was the first of its kind in the country to be run entirely on sustainable energy.

“Our ethos is Good Natured Brews,” Dan says. “So, from the get-go we’ve tried to do everything as best as we possibly could in terms of our environmental practices. But we got to this point where we felt we really needed to be able to walk the walk, as well as talk the talk.”

Beyond gaining the certification, what really excites Dan is something they’ve developed with Pangolan and Climate Active as part of the process: a template for others to follow. Early on in this journey, Capital told their partner organisations they felt that a lot of breweries had the goodwill to become climate neutral but may not know how or where to get started. Now, Dan is hopeful they've set out an easy-to-use process that will make the assessment easier for others wanting to follow suit.

“So, for any brewery that follows, it’s going to be quicker, cheaper and easier,” Dan says.

“You just grab their data – how much grain have you bought from England? How much from Australia? – and we plug those numbers in and it spits out a figure.”

Often when discussing sustainability, the cost of taking action can prove a hurdle, but Dan says he’s tallied up how much becoming entirely carbon neutral has cost the business. His calculations include the cost of the entire audit process – excluding his own time – and it comes to a mere 14 cents per case of beer.

To which Dan says: “At that kind of price, why aren’t we all doing it?

“Our take-home message is it’s not as difficult, time consuming or expensive as you think.”

The Future Is Bright

While Capital's new accreditation might be a first, they aren’t the only brewery looking to become a more sustainable business.

Melbourne’s Moon Dog became carbon neutral at the start of this year, with co-founder Karl van Buuren saying the project started seriously at the end of 2020 and followed feedback from their staff across the business who emphasised sustainability as important to them.

“Things were looking to go back to closer to normality,” Karl says of the time. “So, we put together a plan of what we wanted to do and engaged a consultancy firm to assist us on the journey.”

Working with Point Advisory, they audited the brewery’s carbon footprint, developed ways to reduce their emissions, then offset their emissions by investing in renewable energy projects in the Philippines. Since launching their Preston site, they've installed a substantial number of solar panels at Moon Dog World too, which has played an important role in how they’ve cut their own emissions. They’ve also moved their brewery and venues to a completely carbon neutral electricity supply.

The next step is to achieve official certification from Climate Active and, as part of that, they’re currently diving into Scope 3 requirements, working with suppliers to better understand the emissions caused by packaging material, transport and raw materials.

“We’re trying to make sure we’re not actually just saying we’re doing these things but are really committed,” Karl says.

“We have to maintain it every year. We have to do our inventory and check our emissions and then purchase our offsets and do that every year so it is a long-term commitment we’re making.”

He adds: “When running a brewery, you’re often looking at quality, costs and efficiency, and then you’re slotting in this, which can in some respects be pulling in a different direction – so it can be a different mindset.”

ON NEUTRAL GROUND

Capital and Moon Dog are among a small number of breweries that have achieved carbon neutral status, although certified through through bodies other than Climate Active. Matilda Bay became carbon neutral-certified last year after using the organisation South Pole, which requires businesses to offset scope 1, 2 and all relevant scope 3 emissions.

That accreditation had been a goal for the team since the brewing company’s revival in late 2019: ways to offset their emissions are literally built into their home with 248 solar panels providing around 30 percent of their power and the rest coming from a single wind farm west of Melbourne.

They’ve also offset their emissions by supporting renewable energy projects in Asia, as well as the Myamyn Conservation Project in south-west Victoria. It’s a model the wider Asahi group is reviewing to see whether it could work across other parts of the business.

In Western Australia, brewing sustainably is something Rocky Ridge have strived towards since they launched in 2017. You can read about their Greener Pastures program and how they’ve offset their entire own carbon negative status, while their widespread practices as a business recently saw them recognised as WA winner of the Telstra Promoting Sustainability Award.

As well as utilising rainwater and power harnessed from 250 solar panels, the team at the off-grid, farm-based brewery near Busselton, has been continually looking to improve their environmental performance. They use intensive waste water treatment, property revegetation and tree planting – more than 20,000 plants since launching, and have invested in a fleet of hybrid vehicles, commissioned a carbon dioxide capture plant, and reduced single use plastics and packaging materials across their range.

At time of writing, they are working on installing a hydrogen generator that uses brewery wastewater to replace their diesel generator, further reducing fossil fuel inputs, and helping them towards their goal of achieving net zero emissions by 2025.

GREEN SHEDS

Next week sees Rocky Ridge effectively compete with another brewery for the national title in Promoting Sustainability, after Big Shed Brewing were declared the state winner for South Australia.

While the Adelaide brewery isn’t carbon neutral, they’ve been recognised for their efforts when it comes to reducing water, waste and emissions, particularly through the 606 solar panels now installed on their roof. Visitors to the taproom may have noticed how important those panels are, with a screen showing how much power Big Shed is producing at any one moment.

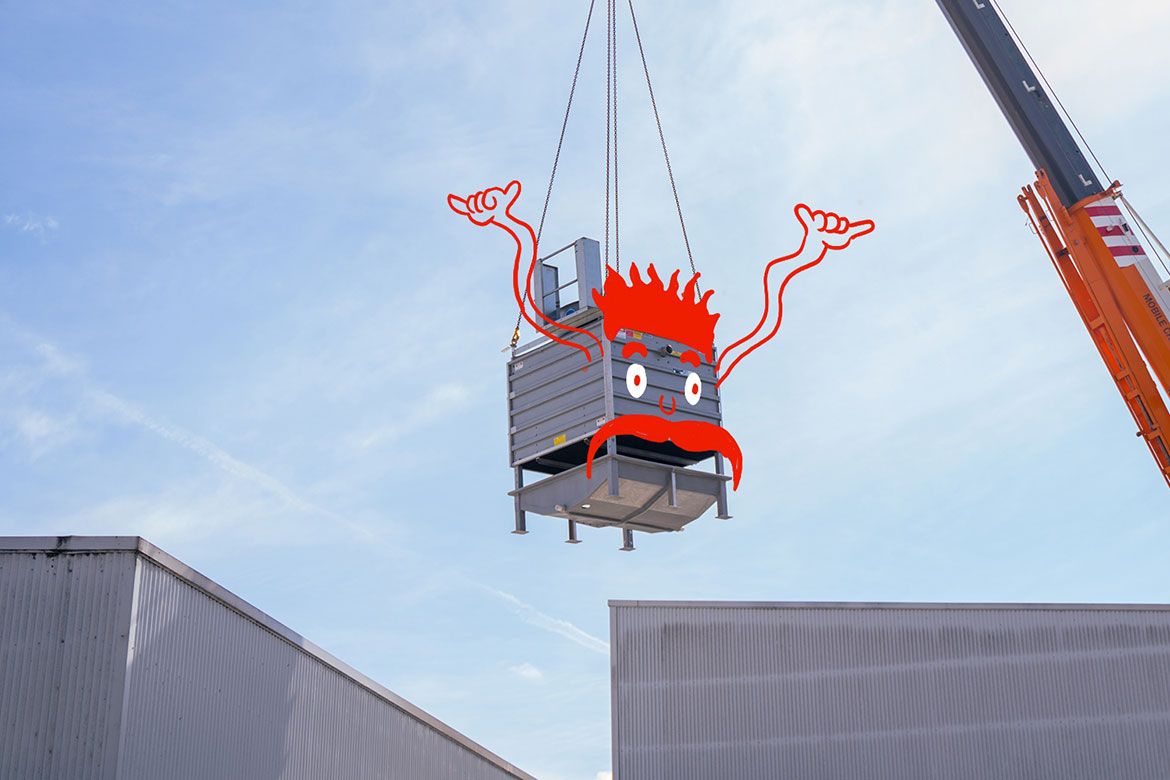

Brewery co-founder Jason Harris (below left with Craig Basford), says the fact both Rocky Ridge and Big Shed have taken out the top spot in their respective states highlights the many ways brewers can commit to reducing emissions.

“The fact we’ve both gone to nationals is cool,” Jason says. “But with one being off-grid and one not being off-grid shows that we’re coming at it from two different aspects of the same solution. It shows you that there’s a variety of things to do just to be in contention.”

Jason says he was flying somewhat solo when entering Big Shed for the Telstra award but thought they could be in with a shot. In an industry where the focus is often on the short-term, he wanted to celebrate how they’ve been looking long-term too.

“We don’t really get up and spruik ourselves and this is exactly what this was,” Jason says.

“We’re used to thinking very short-term: what’s the next batch, canning run or packaging run? Whereas this was very long-term in the making, we were planning our solar for over 12 months.”

Sustainability was always on their mind when building their Royal Park brewery, which opened in 2019, and they've continued to pour much of their revenue into this long-term project.

“We put up 606 panels and the roof is mostly covered,” Jason says. “We made sure we avoided shadow areas and our roof might look like a bit of a hodgepodge of panels but it’s designed to be as efficient as possible.”

What's more, he says that, as they’ve grown, the ability to invest the capital needed to brew more sustainably is more in reach.

“Early on, we couldn’t afford to rub two sticks together let alone put $300,000 on a solar system,” Jason says. “We started our business with $110,000 and we spent three-and-a-half times that seven years later on solar.”

Co-founder Craig Basford adds that it’s important for any brewery to not get too overwhelmed by the issue, believing small businesses that are embedded in their community are adept when it comes to making small-scale changes that can have a wider impact.

“We’re in an industry that isn’t too environmental by default,” he says. “But I do think it speaks to the way breweries attack problems with creativity and a tenacity – you’ve got to have a certain mindset to want to do that.”

Indeed, the desire across the beer industry to better assess sustainability isn’t limited to breweries: suppliers are among those going to great lengths to understand and reduce their own emissions. In August last year, Hop Products Australia launched its first sustainability report after the business became a signatory to the UN Global Compact in 2020. It sees the country’s largest hop grower develop a roadmap and sustainability strategy that sees social responsibility, environmental footprint and responsible sourcing underpin their action.

At Capital, Dan says they're already looking at the next steps beyond certification. They would like to see the industry work together so emissions relevant to breweries, whether upstream or downstream, can be cut out too.

“If we purchase products from other companies that are also certificated carbon neutral then that doesn’t contribute to our footprint at all because that supply has already been accounted for,” he says, before suggesting practical ways in which this can be achieved, such as breweries collectively pushing freight companies to be more sustainable.

“If all the breweries in the country were saying we want to choose a freight supplier that’s electric," he says, "then we would have a lot more sway.”

He'd also love to see the beer industry develop its own carbon offset program, one in which breweries can invest and that visibly captures carbon and changes the landscape.

“The amount of carbon credits that Capital needs to purchase is not sizeable enough to start an entire project," Dan explains. "But imagine if there were enough breweries in the Independent Brewers Association to join together to create a project that could be ACCU [Australian carbon credit units] certified.”

Of the potential for a greener future, he adds: “We can offset our emissions by purchasing carbon credits until the cows come home but the real goal is actually driving down our emissions in the first place to the point where we don’t have to purchase carbon credits. And we can only do that when we work collaboratively with other businesses that share that goal.”

You can read the rest of our Going Green features here.