Matt Lawrence is a maker. From making bespoke suits as a tailor to making beer as a brewer, he’s passionate about creating things that are greater than the sum of their parts.

His newest venture, Grain Totes, Totes Great, is all about reducing waste in the beer industry by transforming the malt bags discarded from craft breweries into tote bags.

He currently makes two styles – a standard tote bag, and one with inset sleeves that holds three cans on either side with a larger pocket in the middle. Each tote is linked back to whichever brewery the malt bag came from, and what beer it was used for.

“I put a little sticker on it that says, ‘This grain was used to make our lager’, and they go ‘Oh shit, I love One Drop’s lager! I’ll buy that bag, and I’ll buy two four-packs.’,” he says.

Matt’s main vision for his venture is to replace single use bags in beer retail. Unlike many other bags, his are strong enough to carry hefty amounts of beer; Matt says he’s stacked them out to 15 or 20 kilos without a problem. But, of course, they can be used for non-beer purposes as well.

“They’re great as a beach thing as they’re fairly waterproof as well … You could almost use them as a Santa bag!”

Matt’s idea came about when his day job with Batlow Cider brought him into the orbit of brewery after brewery and he was confronted with the stacks of malt bags being thrown away. Where the breweries saw waste they had to deal with, he saw material with which he could create.

“I see all these bags getting thrown out, and I’m like, ‘This is a bit of an environmental disaster.’ I get a lot of my bags from One Drop down in Botany, and he’ll go through 20 or 30 or more a week. And I’m thinking to myself, ‘Shit. If he’s just one, imagine the piles in landfill?’.

“With my history of coming from the rag trade, I’m like, ‘What could I do? How could I recycle these or reuse them?’.”

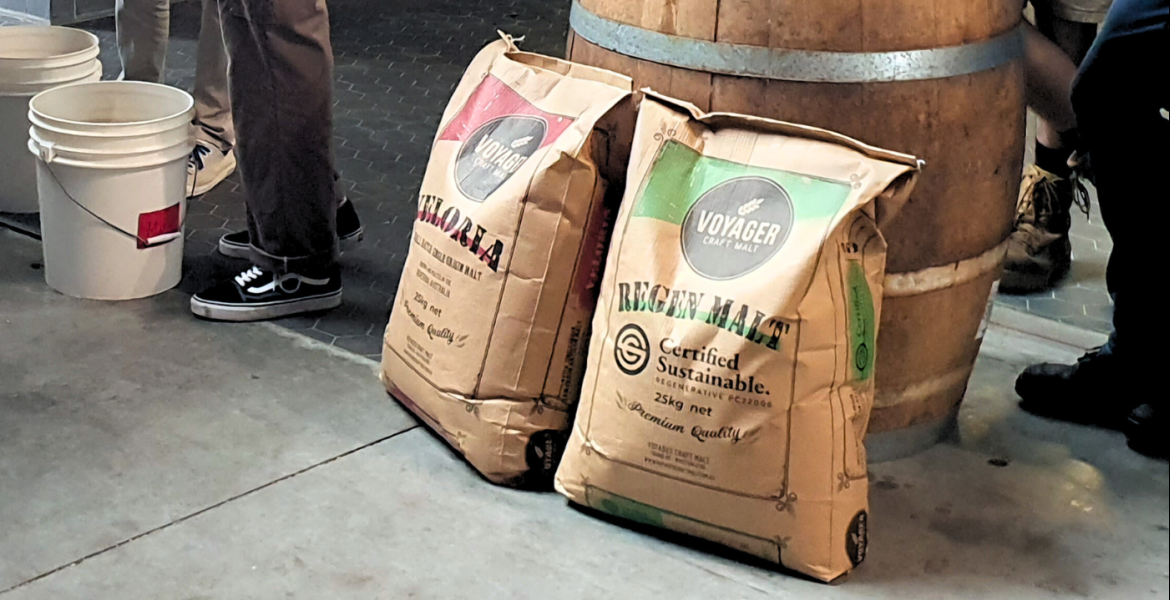

Many malting companies use bags made from durable polypropylene to keep malt dry during storage and shipping. While polypropylene can decompose in around 20 to 30 years compared to the hundreds of years required by some other plastics, Matt saw potential to put the polypropylene jacquard malt bags to greater use. So, after experimenting with designs in March 2020 – as well as overcoming difficulties cutting and sewing the tough material – he started collecting malt bags from breweries across Sydney.

“I walk into every brewery, I dumpster dive at times … most breweries will say, ‘OK Matt, do you want 20 or 30? We’ll keep them for you. Come and see us.’.”

Of course, Matt didn’t invent the idea of reusing malt sacks. Stone & Wood and 4 Pines have introduced upcycled carry bags as sustainable ways to cut down on single use bags, and Your Mates have partnered with environmental organisations to use malt bags to clean up beaches on the Sunshine Coast.

But, while others have made bags from the material, Matt noticed it was only ever on a small scale. He saw an opportunity to repurpose them on a larger scale in the hope of bringing about an industry-wide change that would both reduce waste from breweries and the need for single use bags and four-pack holders when people buy beer.

He sees three things that need to happen for his vision to come to life.

First of all, there needs to be the capability for quality, mass manufacturing.

“I think people have wanted to do something about them, but I don’t know if anyone’s ever had the idea of doing it as a mass production situation. Which is something that I’ve come from.”

As demand for the bags increases, Matt’s home-based operation with industrial sewing machines has ways to scale up.

“I’ve found out a way to lay them and cut ten at a time. I’ve found people who’ll sew them with me," he says. "My dream is that I get it going and the breweries are selling 20 a week, and I pick them up and I cut them and I’ve got two or three ladies I know who’ll put them into their garage, and they’ll sew them for me over the weekend. So we make sort of a home, Australian large-scale recycling operation out of it.”

The second thing is that the final product needs to be relatively cheap. With his current setup, it takes Matt about ten to 15 minutes to cut and re-sew a bag into a tote, which he values at around five or six dollars per bag.

“I’m happy to sell them for no profit for myself – I'm doing this to support the industry – and then have brewers sell them for ten bucks. I’m happy to even give people them on consignment; ‘Hey, take ten! And, if you sell them, pay me then just so I can keep making them!’.

“I’d love to do it for free, but unfortunately kids don’t eat for free!”

As with any manufacturing, it’s a numbers game – once the product can be made on a larger scale, the manufacturing cost per item can come down. For malt bag totes, this means turning them from an expensive novelty product into an affordable everyday product.

“Some people sell them for 25 or 30 bucks… I really want to try to get them down to selling them for two bucks! I don’t know if that’d doable in Australia, but I could always try.

"More we make, cheaper they become. Cheaper they become, more we sell.”

Which brings us to the third thing needed for these bags to really take off: industry support. Matt’s been delighted by the support of the breweries who have supplied him with malt bags, and has received endless personal encouragement from his employer, Batlow Cider.

His biggest customer to date has been Gladfield Malt, who put in an order for five hundred totes to be given to attendees at BrewCon 2021.

Gabi Michaels, co-owner of the New Zealand malting company, says, “Due to COVID travel restrictions, the possibility for me and Doug not to be present at the event was pretty high, so why not cause an impact by sponsoring the goodie bags? Everyone will ‘see’ us there! Also supporting the initiative to help BrewCon ideas about sustainability and Matt’s business was a no brainer for us.”

While the conference has subsequently been cancelled, the order allowed Matt to step up production and build his stock levels. Matt says all that needs to happen now is for breweries and bottleshops to buy into the vision and come on board.

“If everyone put it all together, and took it as an industry-wide initiative, they could become reasonably priced enough that you keep using them. Because the supply of the bags is almost limitless!”

His dream is that bottleshops and breweries will sell the bags on to customers who buy a couple of four-packs; “Take off the tetra pack on the top, recycle that, put them in the bag.”

And Gabi from Gladfield has bought into the vision of repurposing malt bags to create a far-reaching change.

“I would like to see all the brewers who sell beers on-premise use their purpose made malt bags as their beer packaging,” she says. “It will create a lovely chain and feel-good factor, and the bags when well made are great for carrying to supermarket, farmers market, kids swimming bags … you name it!

“We will do anything we can to support Matt and others on this idea. Other clients here in NZ and Rarotonga have come up with similar ideas and we are right behind them on whatever they need.”

On a personal note, this writer can vouch for both the functionality and the cool factor of repurposed malt bags, having used them to haul beer samples across the city on several occasions. And that’s even before the sustainability factor comes into play.

“I know they're a little bit more expensive than 99 cent bags from Woolworths,” Matt says, “but we’re keeping something from landfill, and we’re re-using, recycling. And they’re pretty cool.”

If you're a brewery or bottleshop wanting to partner with Matt, you can contact Grain Totes, Totes Great via Facebook. You can find other articles in The Collaborators series here.