As the craft beer industry and the audience for its beers grows, is there anything more crucial to its ongoing success than quality? With more people than ever before stepping away from mainstream beers to try something new, their first experience needs to be a good one otherwise they may be put off ordering a second.

Sure, a bad experience could stem from ordering a beer of a style they simply don't like, which is out of a brewer's hands (unless they're drinking at their bar, in which case they could be guided towards something akin to their tastes). But if it comes from trying a faulty beer – maybe faulty when it left the brewery or one that's developed faults over its time in trade through poor packaging or bad handling along the distribution chain – then it's something that could and should be avoided.

Thankfully, over the time we've been involved in the Australian beer world, there's little doubt that overall quality has been improving. There were multiple occasions prior to launching (and in the early days of) The Crafty Pint where we'd visit a brewery and, even armed then with a naive palate, knew that some were serving beers – sometimes an entire range – that were hideously infected or terribly brewed.

Such happenings are scarce now, although we've still visited cellar doors in the past 12 months and been shocked that a brewer would allow some of the beers on offer to be poured inside their own venue where there is absolutely no excuse for substandard product. What's more, in selecting beers for a new book on Australian beer* coming out later this year, there have been brewery lineups we've tried that feature a mix of quality hits alongside ropey misses.

While the bar continues to rise, with the best Australian brewers producing beers as good as any in the world, there's still a long way to go. And, with more and more brewing companies entering the scene, the need for them to be up to standard from the off becomes increasingly important. Natural selection should ensure poor brewers go out of business, but it would be better if there were no poor brewers at all.

So, for our first Big Issue of 2016 feature, we address what is possibly the biggest of them all: quality.

To do so, we approached six people from different areas of the industry and sought their responses to a range of questions on the topic. They're presented below in what is a long read, but one that we believe will prove not just interesting but useful to those who care about the country's craft beer scene.

THE PANELISTS

The six contributors we approached are:

- Brendan Varis – owner and head brewer of serial champs Feral Brewing, an experienced international beer judge and a significant player in the Craft Beer Industry Association.

- Chuck Hahn – one of the founders of the craft beer scene in Australia who is still heavily involved in various projects, including James Squire, Knappstein, Kosciuszko and New Norcia, within the Lion business. He is also a board member of the Craft Beer Industry Association.

- Jayne Lewis – co-owner and head brewer at Two Birds Brewing, which has been collecting trophies for fun, Jayne is also a respected international beer judge and a key player in the Australian wing of the Pink Boots Society.

- Tim Wills – the Australian sales rep for Premier Stainless Systems, which designs and supplies equipment to breweries across Australia, he has a career in craft beer stretching back more than three decades and taking in beer bars across North America before he moved to Australia.

- Pete Mitcham – better known to many as Professor Pilsner, Pete has been writing on beer in Australia far longer than most, is one half of the Radio Brews News podcast team, an associate AIBA beer judge and experienced steward, beer educator, event host and... you get the message.

- Michael Jackson – head of merchandise at Dan Murphy's, the national retailer responsible for putting more craft beer into Australians' hands than any other.

THE BIG ISSUE

1. How do you define "quality" when it comes to beer?

Brendan Varis: For us at Feral, quality is a two part process. The first part being subjective and relating to product development and the finesse of a beer. This is really defining for a brewery as it represents why you do what you do. Not everyone will agree with you on whether or not you have done a good job on this part of a beer's quality but it doesn’t matter so long as it represents what you want it to be. This subjective part is difficult to define and even more difficult measure.

The second, objective, part relates to adhering to production specifications, processes and standard operating procedures to ensure accurate and consistent recreation of beer each and every time it is brewed. This is very measurable and can be defined simply as brewing beer that consistently meets specification.

Chuck Hahn: Quality involves the deliverance of consistency in a beer, but it goes further than that in that this consistency must be acceptable to the palate of the consumer. It must be of good quality. The larger brewers are absolutely passionate about consistent quality in their brews.

Jayne Lewis: To me, it’s the technical aspects that can be measured, such as alcohol, CO2, and bitterness, as well as the more intangible / unmeasurable elements, such as balance, freedom from faults and presence of appropriate flavour and aroma characters.

A quality beer consistently meets technical specifications, is free from infection, displays the desired flavour and aroma characteristics and meets customer expectations.

Tim Wills: Pristine flavour, freshness, biscuit, mouth-watering, refreshing, balance from hops and malt. I have gone to quite a few places in the States with more than 50 taps and it always impresses me that for the most part they all taste super fresh.

Pete Mitcham: As a basic, entry-level concept, I think quality has to mean “free from faults”. That’s fermentation and packaging faults first and foremost. I think the concept of "quality" sometimes gets swept up in criticism about "out-of-style" issues, which I think come second to brewing QC protocols.

Michael Jackson: A great, fresh product with consistency in standards.

2. What do you think of the overall standard of craft beer being produced in Australia?

BV: I think it’s now easier than ever for consumers to be able to access a high quality craft beer no matter what their subjective preference may be with regards to flavour, taste and style. The needle has really moved in this regards and is a huge win for consumers who even just half a dozen years ago would really need to go out of their way to find quality beer. That said, with craft beer being more readily available and accepted, it has become easier for consumers to unknowingly purchase beer of questionable quality.

CH: It is reasonably good at the moment, but I can see tough times ahead. I had one craft connoisseur remark to me: “I go into a craft pub now and I must try to decide from over 24 beers on tap – most of them high ABV, high BU’s [bitterness units] and practically undrinkable.”

Each craft brewer is trying to mark their mark with something very distinctive. This will gradually settle down, but then we may face ageing in the beer lines and beer oxidation. Not good things for consistent good quality deliverance.

JL: One of my favourite things about being involved in judging something like the Craft Beer Awards is getting a snapshot of the industry as a whole. I was really impressed in the jump in quality from 2014 to 2015 and how few really low scoring, grossly faulty beers we judged this year.

I think overall the quality is improving, but I believe that it can still be hit and miss and there is still work to be done.

TW (pictured right): I think that our craft beer quality has had a big increase in the last couple of years. At the recent Warner Bay beer festival, 25 percent [of beers] needed some work, 55 percent of the beers tasted well balanced and fresh, 15 percent were very good and the top 5 percent would rate highly anywhere in the world.

TW (pictured right): I think that our craft beer quality has had a big increase in the last couple of years. At the recent Warner Bay beer festival, 25 percent [of beers] needed some work, 55 percent of the beers tasted well balanced and fresh, 15 percent were very good and the top 5 percent would rate highly anywhere in the world.

PM: I think the beer community has been its own best ally in the fight for improving beer quality. With so many brewers entering the fold and getting their beers to market, there is no room for stragglers or slackers. In turn, the market is becoming more aware of "how beer should taste" and is less likely to allow poorer performers to proceed.

MJ: The beers coming out of Australia right now are diverse and very exciting. Our customers are branching out to try them and the feedback has been positive.

3. Do you think it is improving?

BV: I think the consistency and quality of draught beer has seen significant improvement. The days of only ordering a small beer (insert state appropriate term here) due to fear it may be difficult to finish a pint have gone for me. There is now a solid core of Australian craft breweries who I trust enough to jump right into a pint and, importantly, their beer is becoming more readily accessible on tap.

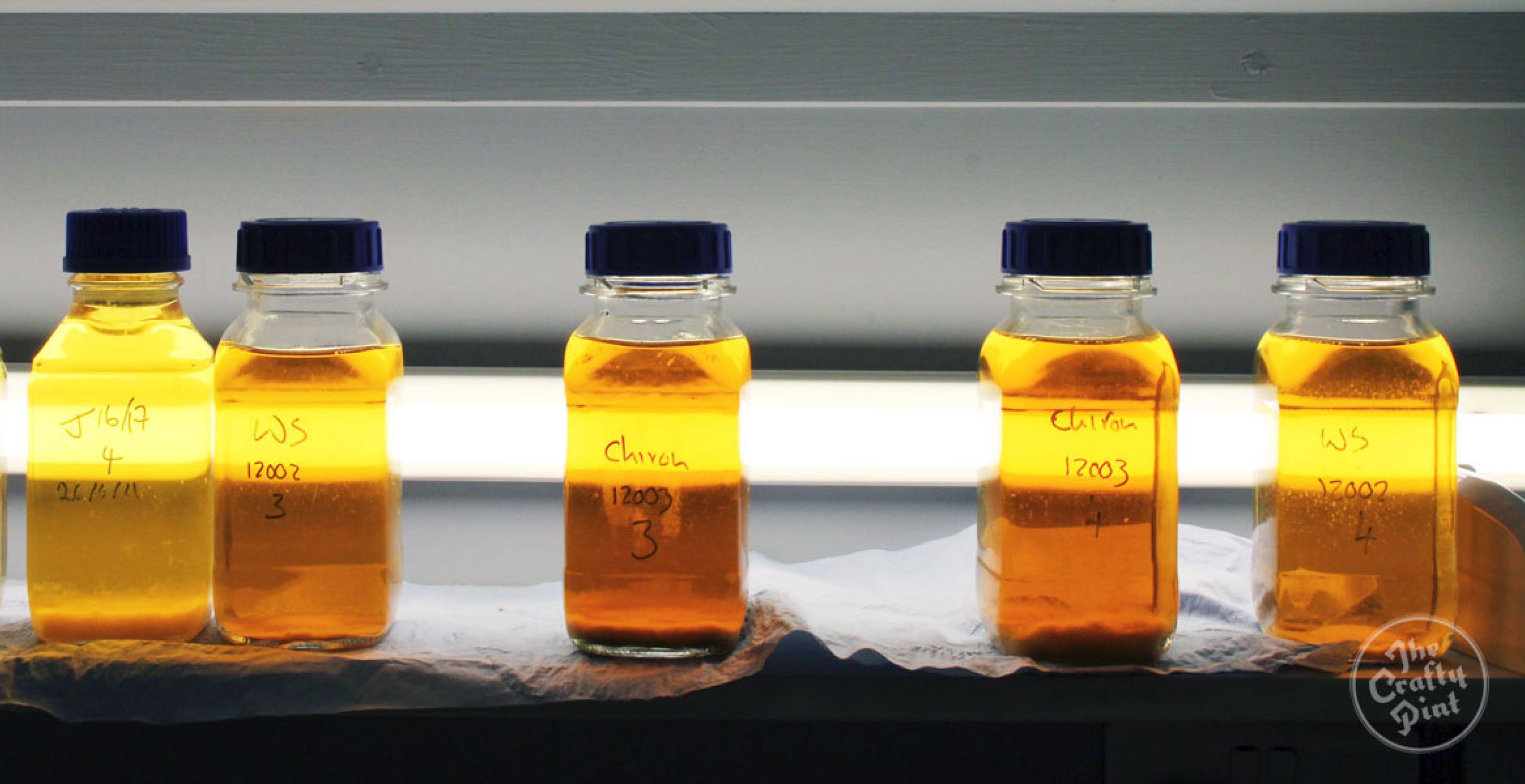

When it comes to packaged beer, things are still a little bit hit and miss but definitely moving in the right direction. The encouraging thing I regularly see happening now is breweries reinvesting in themselves to improve quality. So that may be instruments to measure quality or bottle fillers to reduce air or any number of other investments. I really think a lot of breweries are putting quality high on their priority list.

For example, the old delivery truck can just be kept running for a little longer so a brewer can instead go and buy a bit of lab gear that costs more than a new truck. These type of decisions are being made today by Australian brewers and they should be applauded and supported for it.

CH: At times, I feel it has. Then I run into a series of brews that are practically undrinkable for a variety of reasons.

TW: Absolutely! There is always going to be room for improvement but I think the Australian craft brewers are a pretty determined bunch of people!

MJ: The accolades the Australian craft scene is gaining internationally is testament to the improvements that are being made. The sharing of knowledge between brewers and new entrants to the scene is driving constant improvements and customers are benefitting because it is creating a greater diversity of products.

4. Whose responsibility is it to drive higher standards: individual brewers, their peers, customers, judges in competitions, commentators in the media, someone else?

BV: We operate in a free market economy and ultimately the consumer will drive higher standards. As more brewers get better at what they do and more high quality beer becomes the norm, consumers will become more educated and poor quality beer will become recognised for what it is.

CH: It starts with the individual craft brewer in developing a recipe and procedures to maintain high quality. The brewer must follow that quality drive through to the consumer. Media just assist in informing the public about the great range of flavours and aroma available for savouring and enjoying.

JL (pictured right collecting a CBA trophy): Ultimately the responsibility rests with the brewers themselves, but it would be a great help to the industry if everyone "buys in”.

It’s important for brewers to give feedback to their peers if there is an issue with their beers. It can be a difficult situation to navigate, but I’ve always been grateful to friends of mine who have notified me if we have a problem with a beer in trade. No brewer is immune from the occasional issue, so the more open the communication, the better the beer is that ends up in customer’s hands and the less damage is done to the brand and the industry as a whole.

Judges' feedback can be invaluable, if you choose to listen to it. In my experience, the quality of feedback from the AIBA and CBA has improved immensely in the last one to two years and we have been able to use the feedback to really fine tune our beers. Judges' feedback may also help to give brewers an understanding of their own blindnesses in sensory, so that they can appropriately build sensory panels that account for these blindnesses.

Venues are particularly important, as they have direct contact with the public, so they see how beers are received. It is incredibly helpful if feedback – positive or negative – makes it back to the brewers, so that any adjustments can be made.

Venues can also directly impact the quality of beer, both by the storage of the product and the maintenance of their draught lines. It’s important to foster good relationships with the “front line” of beer operations, to ensure that beer is making it to the consumer in the best possible shape.

TW: I think it is the brewery owners and individual brewers who will need to drive that train.

PM: Whilst I firmly believe that quality is a collaborative effort, it really has to start and finish with the brewer. From mashing in through to bottling brewers need to be vigilant.

At the end of the day, our reputation as a market category starts with the beer. It needs to be as good as it can be. Once the beer leaves the brewery the mantle of stewardship passes to the sales and distribution guys and then the retailers and venue owners who must appreciate the responsibility they have to that beer and that brewer.

MJ: At Dan Murphy’s the customer is our main priority and we value their feedback immensely – it’s essential to ensure the delivery of a great range and better quality products.

5. Are there obstacles preventing the improvement of beer quality and consistency in Australia?

BV: No, not really, but quality comes at a cost and how important it is to a brewer will determine how much they are prepared to pay or what they will forego to achieve it. People's motivation for being in the brewing game can often be exposed here.

If you got into it because of a love and passion for great beer then your decisions around quality will lead you in a certain direction. If short term financial gain is your primary motivator for producing beer you will make different decisions. If, as an industry, enough of us put quality high on the agenda then it will expose those who chose not to value it.

CH (pictured right): Warm climate. Difficulties in maintaining a cool distribution system for the vast volumes of unpasteurised products.

Individual brewery hygiene and the desires of some breweries to venture into souring micro-organisms and other bacteria to produce funkiness. Us older brewers work like mad to eliminate such bacteria from our breweries!!!!

JL: I imagine the biggest obstacles to beer quality and consistency would be money and time, which are essentially the same thing. Breweries are busy environments, most are understaffed and, in the daily grind to pump out beer, it can be difficult to prioritise lab and sensory analysis. We see it at Two Birds all the time; when things get busy, it’s the first thing to fall away. It seems to be the “non-essential” part of brewing, when of course, the opposite is true.

Also, lack of education and / or experience of some brewers and company owners can be an obstacle to beer quality.

TW: I think the biggest obstacle is the lack for refrigeration in both product storage and shipping and venues that don’t have a cold room, where kegs sit at room temperature and pour beer through a cold plate. It will be difficult for customers to be able to drink the beer as the brewer intended.

PM: I think most brewers would quote cost as the major hurdle to ensuring consistent quality. Centrifuges cost big dollars as does a reliable, state-of-the-art bottling or canning line and the tools to test along the way. As a non-brewer, my opinion is that you can’t afford not to have these checks in place.

Knowledge is the other side of this coin. All the lab equipment and fancy pipes and pumps are no good if the person doing the testing can’t interpret the data.

MJ: The rapidly expanding brewer base can lead to a lack of consistency in the quality of products coming through. Investments in infrastructure could also assist in the delivery of better products.

6. What one thing do you think could most help drive improvements in quality and consistency?

BV: If we were to assume that beer at the brewery door ready to ship is high quality and in spec (big assumption, I know) then the single biggest thing most brewers could do would be to store and transport cold as far as possible into the distribution channels. The hoppier the beer the more important this becomes because the fact is that all those delicious dry hop aromas and flavours that we love when a beer is fresh are highly volatile and they quickly become unpleasant if a beer is mishandled and aged for any extended amount of time.

CH: Cleanliness is next to godliness.

JL: One thing? Come on, you know me better than that!

I guess if you only do one thing, then make it lab analysis. Be sure to monitor the brewing, fermentation, storage and packaging process. You can’t control what you don’t know or don’t measure.

If you do two things, then bring in sensory analysis also. Even just tasting the beer throughout the process and sitting around with your brewery staff or a brewing mate, tasting the beers, can help you to pick up faults or deviations from style.

If you can swing it, spending five minutes doing concentrated sensory analysis on every beer will pay even greater dividends.

Also, ask for help if you need it. Luckily enough, we are part of an extremely helpful industry, so call on a trusted associate for a second opinion.

Fostering a culture of “quality, first and foremost” and continuous improvement within the brewery is also helpful.

TW: At a risk of repeating myself: refrigeration, refrigeration. Please keep it cold!

PM (pictured right): Collaboration.

PM (pictured right): Collaboration.

Maybe there’s a way to share knowledge and even equipment if capital is keeping some smaller brewers from tracking their processes.

In the near future we might see several brewers sharing floorspace and therefore tools and techniques to further improve quality.

MJ: It is vital brewers ensure they are practising strict quality control over all of their releases.

7. Should there be minimum standards in place in breweries?

BV: Unsure on this but probably not. I was in Epernay, France, last year and the Champagne appellation controls really surprised me as to how far they reached and how invasive they were on growers and producers. “Champagne” as a brand is considered across the globe to be of very high quality because of that. [Yet] you can still find a broad range of champagne quality produced despite these controls and interventions.

I think it probably comes back to the free market thing: if you fail to prioritise quality your beer will suffer and as consumers become aware of that they will spend their money on a beer they can trust to be of consistently better quality.

CH: Yes, this is something we always insist upon as we have a larger brewery mentality to deliver that consistency through absolute standards.

JL: It’s up to the individual brewery, but basic lab work isn’t difficult to do or expensive to set up. It just requires commitment.

You could be set up to measure SG, pH and do yeast counts for less than $1,000. For CO2, add on about $1,500 and for about $2,500 to $3,000 (worth every single cent) you can get a handheld density meter. Money spent on quality is an investment in the future success of your brewery and is money very well spent!

Endeavour to taste beer out in trade and keep samples for tasting down the track. It’s awesome to taste your beer fresh out of the bright beer tank, but how does it travel and how does it taste after it’s been sitting in the cellar of a pub for six or even 12 weeks?

TW: With the exception of lab equipment, I think those standards are currently in place at most breweries. I don’t think we need to have any regulatory body that is checking on those standards; without the basics any brewery without those practices will not be around very long.

PM: The CBIA or another industry group could probably put together a bit of a Best Practice guidebook for brewers which would outline the basic kit needed to ensure quality. A simple checklist might be all some new players need to get them started on the right foot. A "How to care for My Beer" leaflet would be of great benefit to retailers and venue managers.

Knowledge is power!

MJ: Absolutely – like any consumable-based market, all products produced for human consumption should adhere to the correct checks and balances.

8. What are the risks – to individual businesses and / or the industry generally – if quality isn't at the heart of what every brewer does?

BV (pictured far right collecting an AIBA trophy): Time will tell on this one but internally we hold the belief that quality is the key to sustainability.

BV (pictured far right collecting an AIBA trophy): Time will tell on this one but internally we hold the belief that quality is the key to sustainability.

CH: YES [this is a risk] in a big way.

Small craft breweries used to be noted for two things: making very distinctive beer and going out of business.

Consistency in quality, distinctiveness in brews and drinkability in enjoyment are the cornerstones of good craft brewing.

JL: Quality, or lack thereof, is the single biggest risk to the industry and also to businesses. There is a risk that a customer who has a bad experience with a beer could be turned off a brand and, potentially, turn away from craft beer as a whole.

Quality should be a focus for everyone involved in all aspects of breweries, from production through to sales. All of the real success stories in the industry have a focus on quality, so there is definitely a connection between quality and growth.

TW: At the end of the day, if you don’t keep your product to a high standard your brewery will not be sustainable and will not be in business for very long. I think our industry is healthy and moving in a positive direction.

PM: As much as we like to think of ourselves as a world apart from the big brewers making factory-quantity mainstream beer, we must also admire the effort they put into Quality Control. We can embrace a sense of "vintage" and seasonal variance, but we can’t allow substandard product to find its way into the market. A new visitor to Good Beer can easily be sent back to the secure safety of Big Beer with a bad experience.

MJ: The popularity of craft beer will only continue to grow and competition is vital to ensure the very best products are on offer for customers. The key is to provide consistently good products that customers are willing to try and come back to purchase again.

Thanks to all of the contributors for taking the time out of their busy schedules to respond. There's a remarkable consistency in many of the answers, with the key messages seemingly being to attach great importance to quality, ensure venues know how to treat beer and keep the damn stuff cold!

Look out for more Big Issues features throughout the year or check out our past ones on Ownership and Branding.

Photo of Tim Wills taken from his LinkedIn profile, copyright Jason E Kaplan 2013.

* If you're a brewer that wishes to be considered for inclusion in the forthcoming book, there may still be time. Email ASAP.